一. 产 品 简 介

Product Introduction

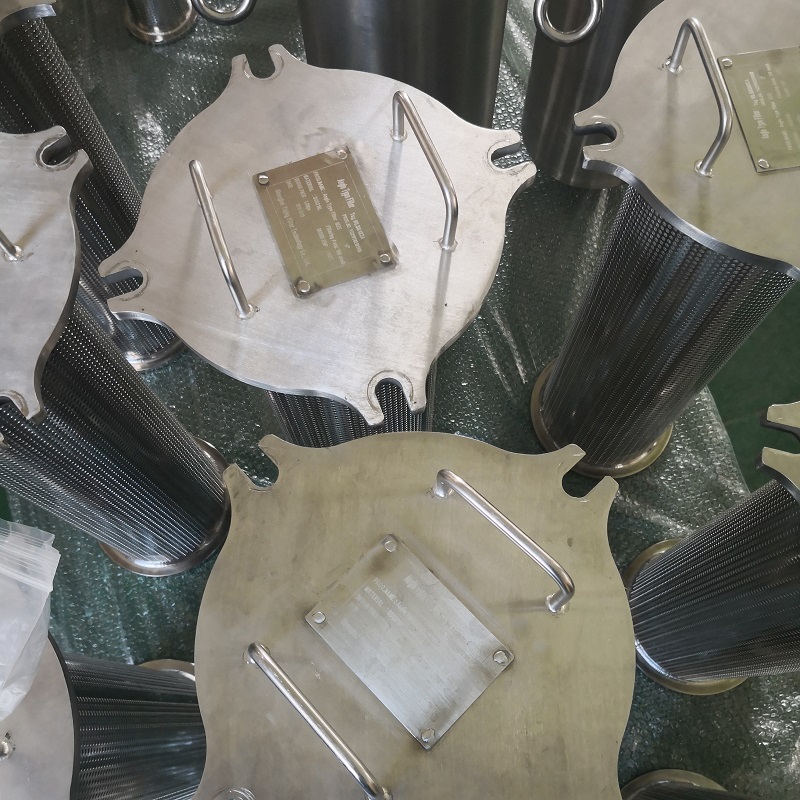

1、简介

Introduction

奕卿科技过滤器用于阻止杂质进入应用管路。较大的杂质被过滤在滤网的一侧,而介 质则通过流出以满足工况的需要。当滤网前后压差过大或滤网被损坏,可以进行清洗与更换。

YIQING filter is used to prevent the particles of the medium from mixing into the subsequent pipeline facilities. The larger particles or impurities will remain in the filter cartridge after the medium flow into the proper filter cartridge through the inlet. The filtered medium will flow out of the outlet and meet the requirement. When the surrounding pressure of the filter exceeds the requirement, or when the filter cartridge is damaged, you can remove the filter cartridge, clean it or replace it, and re-install it.

2、操作原理

Angle Filter Operating Principle

奕卿科技过滤器工作时,待过滤的介质由入口流经滤网,通过出口进入用户所须的管道进行工艺处理,水中的颗粒杂质被过滤留在滤网内部。当被过滤下的颗粒越来越多,过滤速度逐渐变慢,滤孔会被阻塞而变小,此时将滤网取出清洗干净,并重新装入后系统正常运行。

WhileYIQING filter works, the process medium to be filtered flows into the filter from the inlet, through the filter and outlet into the subsequence process pipeline, the particles in the medium trapped inside the filter. More and more particles trapped down, filtration speed slow down, filter hole will be tuffed, then replace or clean the strainer, operation could be continued.

二、安 装

Installation

准备

Preparation

1、首先,请确认安装直角过滤器所需的配件准备齐全;

First of all, please confirm accessories required by the system are ready.

① 过滤器本体 ② O 型密封圈 ③ 支撑网 ④ 筒体密封圈

① angle filter body ② O-type ring ③ inside metal basket ④ cover O-type ring ;

2、若 O 型密封圈变形、出现划痕或破裂,请更换新的配件;

Check O-type ring and inside metal basket, if the O-type ring deformation, scratches or rupture, or the inside metal basket joint groove has problems, please replace the new accessories.

安装

Installation

安装时,请按下面步骤操作:

Please follow the installation operation steps:

1. 将过滤器安置在其工位上,连接进口法兰或快接后并加以固定,闷堵排气口或配置排气阀;

2. 松开顶盖上的吊环螺母、螺栓,将顶盖转至合适位置或取开顶盖;

3. 将金属滤网轻轻放入过滤器中,使滤网底部与过滤器内密封面贴合;

4. 将 O 型密封圈放入凹槽,O 型密封圈不能扭曲或变形;

5. 将顶盖对齐滤网,缓缓放在筒上与内置过滤框相吻合;

6. 旋转顶盖与直角过滤器筒体法兰对齐,扣上吊环螺栓,拧紧吊环螺母;。

7. 关闭安装在过滤机顶部的排气阀;

8. 检查连接管道是否牢固,工作压力是否在允许范围内;

9. 打开管路出口阀门;

10. 慢慢地打开入口阀门让介质缓缓流入并充满过滤器以防止液体突然冲击滤网,造成破裂,然后观察有无泄漏。若未出现泄漏,即可投入使用;

1. Put the filter on the right position, connected with the inlet flange or clamp and fasted it, stuffed the exhaust port or install an exhaust valve.

2. Unscrew the lifting nut, turn the cover to a reasonable position or take it off.

3. Put the metal inside basket into the filter, confirm the basket and the filter inner face be well sealed.

4. Put the O-type ring into the groove, O-type ring cannot be distorted or deformation.

5. Put the cover to the proper position aligned with the inner metal basket.

6. Rotate the cover and buckle bolt, tighten the nut .

7. Close the exhaust valve if existed at the top of the filter.

8. Be sure the connection pipe is well fastened and whether the working pressure is within the allowable range.

9. Open the outlet valve.

10. Slowly open the input valve to prevent sudden shock, and then observe whether the leaks. If no leakage, filtering can begin.

三、日常使用及维护

Usage And Maintenance

|

提供专业过滤方案 |

YIQING 奕卿科技 |

|

|

|

|

日常使用 |

|

|

Usage |

|

工作中的过滤器需经常检查进出口的压力差,当压力达到 0.05-0.1MPa 时,应及时更换清洗滤网,避免压差过大使滤网破裂或损环;

Filtration system should be regularly check the import and export pressure, when pressure difference is 0.05 to 0.05 MPa, should clean or replace the screen timely to avoid screen rupture or damage.

正确打开过滤后的滤机上盖

Open Filter Cover Properly

警告:在直角过滤器内有压力的情况下,不要打开顶盖,否则剩留液体可能喷出,造成液体流失和人员伤害。

Warning: do not open the filter while the filter in pressure, the leaving liquid overflowing

may cause loss of fluids or injury the person.

请严格按以下顺序操作:

Please operate in the following order:

1. 关闭管路入口阀门,若过滤器出口处有压力时,请关闭过滤器出口阀门;

2. 确认排气阀所接管道已被接到安全位置(在过滤有毒有腐蚀液体时尤须注意),再打开排气阀,防止液体对工作人员及周围环境造成伤害和污染;

3. 检查压力表,确定内部压力为零,将过滤器已与管道系统分开;

4. 有排泄阀的,确认排泄液接到回收处。打开排泄阀,将过滤机器的剩留液体经排泄阀流尽,关闭排泄阀。此排放工作可配合加压方式完成(请参考加压排放过程);

5. 拧开上盖吊帽,转开或取走顶盖;

1. Close import valve, while export pressure is not zero, close export valve.

2. Confirm the exhaust valve outlet pipe has been received safety (especially pay attention to in filtering toxic or corrosive liquids), and then open the exhaust valve, avoid the liquid damage and pollution to the staff and the surrounding environment.

3. Check the pressure gauge, if the internal pressure is zero, separate the filter from pipeline system.

4. If a discharge valve exist, confirm fluid drain safty, open the discharge valve. Till liquid in the filter be discharged off, close the drain valve. The discharge of work can be done with pressure mode (please refer to the pressure discharge process).

5. Unscrew cover cap, turn off the cover or take it off.

清洗滤网:

Clean Screen

1.正确打开过滤器顶盖;

2.将过滤框小心取出;

3.用干净液体冲洗滤网表面的杂质,冲洗时注意不要正对滤网表面,建议与过滤网斜

30 度冲洗。注意不要将滤网冲脱焊(因滤网为耗材,如脱焊需重新采购);

4. 放入清洗好的滤网(请参考安装过程);

1. Open the filter cover properly.

2. Take the inner metal basket out carefully.

3. Flush the metal screen, don't rinse it directly to the mesh surface, the angle may be 30 degrees. Pay attention to the screen don't take off the welding. (due to mesh for consumables, such as sealing off need to purchase)

4. Put screen cleaned clean filter, please refer to the installation process.

四、监控过滤质量

Check Filtration Quality

在液体输入压力稳定的情况下,过滤质量与滤网内外的压力差密切相关,如果压差太大,说明滤网的过滤孔径已堵塞,过滤速度下降。因此,建议当过滤器开始工作后,定期检查压差来决定更换滤网的时间,一般滤网能承受的压差为 0.05~0.1MPa 左右,当压差达到这一区间时,应及时清洗或更换滤网以避免滤网破裂,影响过滤效果。如果压差突然下降,应立即停止过滤,并检查是还发生泄漏。

While liquid input pressure is stabile, filtration quality is closely related to the filter pressure difference inside and outside, too big pressure difference states that the metal screen is blocked, filtration rate decreased. So when start working, the differential pressure should be regularly checked , general mesh can withstand the pressure difference is 0.05 to 0.1 MPa, when the pressure difference reaches the range, should be clean or replace the filter to avoid screen broken and affect the filtering effect.

If the pressure difference drops suddenly, please stop filtering immediately and check whether the metal screen is leaked.

特别声明:

Special Statement

1. 正常使用情况下,奕卿科技过滤器质保一年,滤网及密封圈等耗材不在质保范围之内,如由于使用不当造成损坏不在质保范围。

2. 奕卿科技过滤器设计压力为 1.0MPa,推荐最大工作压力为 0.6MPa,特殊规格除外。

1. Under normal use,YIQING filter, one year warranty, filter and sealing ring material is not in the scope of warranty, such as damage due to improper use is not in the warranty scope.

2. the design pressure of YIQING angle filter is 1.0 MPa, the recommended maximum working pressure is 0.6 MPa, except for special specifications.